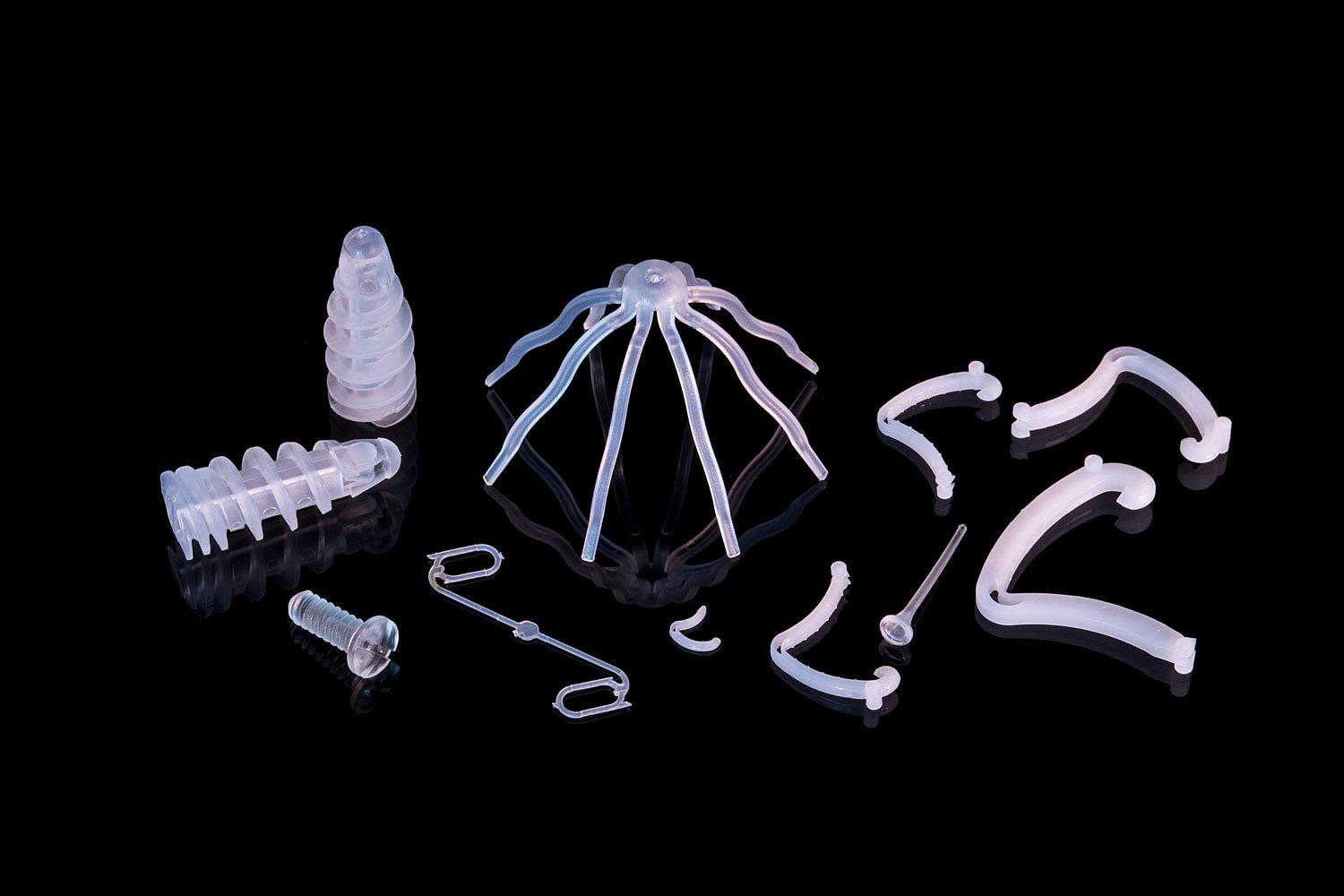

Cleanroom ISO 8 for Molding and Assembly

Matrix Plastic Products has the equipment and expertise to handle cleanroom plastic injection molding and assembly projects in our ISO 8 (Class 100,000) certified cleanroom. High Efficiency Particulate Air (HEPA) filters regulate airborne particulate count, and a positive air pressure is maintained throughout the cleanroom to prevent contaminants from entering whenever personnel enter or exit. Our cleanroom features operator gowning areas, assembly workstations, and lower-tonnage electric molding presses for clean and quiet operation.

Bioresins and bioresorable materials, such as the PLA, PLG and PGA families used in implantable devices, are susceptible to hydrolytic degradation before and after the molding process. These resins must also be dried to less than 0.02% (200 ppm) and the finished product must be maintained dry. For these reasons, our ISO 8 cleanroom is equipped with a specially designed HVAC system to control humidity and temperature. Refrigeration units store raw resin at the prescribed control temperature, and we nitrogen flush and vacuum pack finished parts with a desiccant.

_horizontal_white_536x129.png)